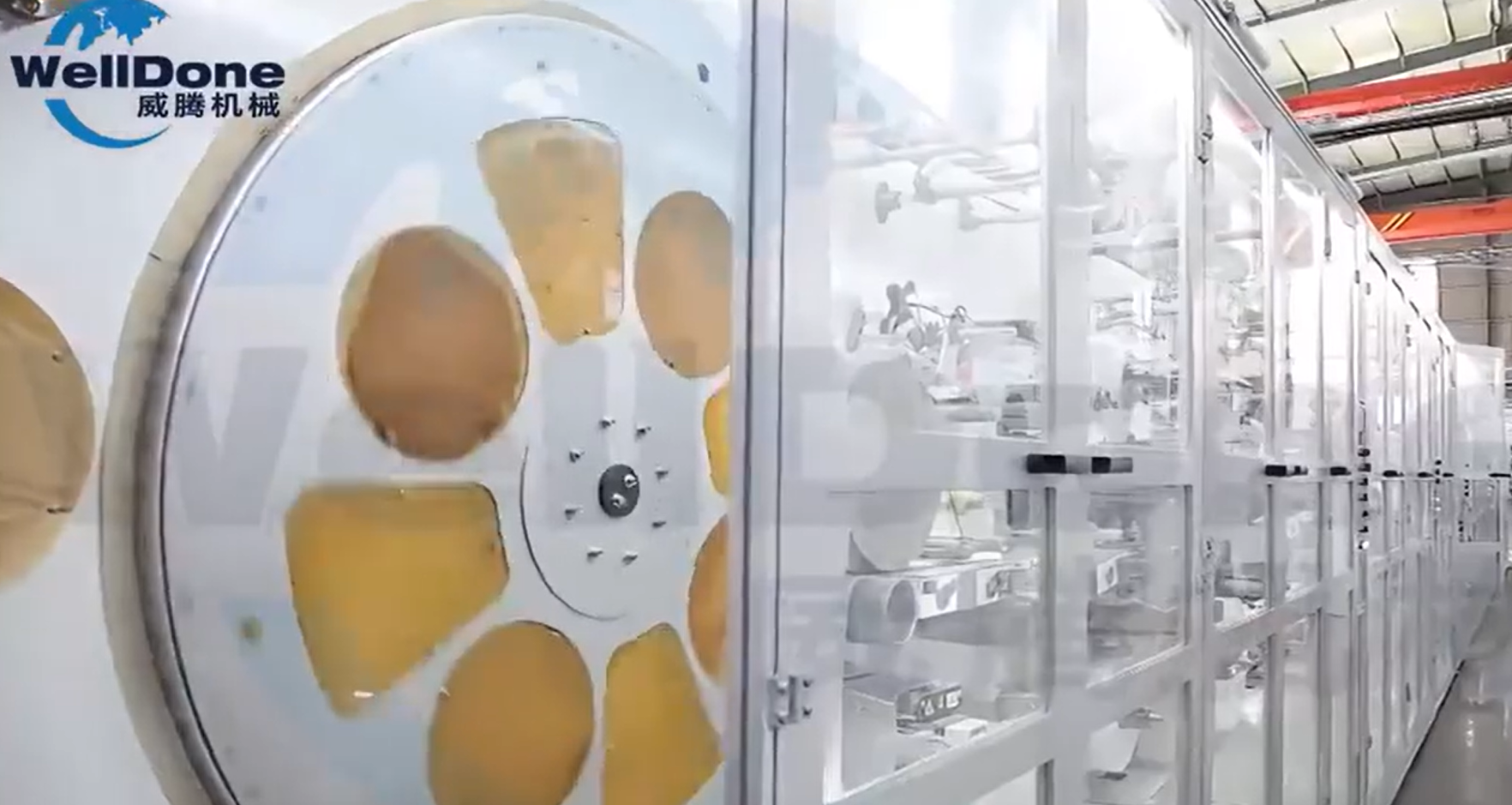

Boost Your Diaper Production with I-Shape Baby Diaper Machine – Engineered for Efficiency and Comfort

Looking to expand your baby diaper business with a high-speed, reliable solution? The I-Shape Baby Diaper Making Machine from Welldone Machinery is your best choice for precision, efficiency, and customization.

🌟 Why Choose Welldone’s I-Shape Diaper Machine?

✅ High-Speed Output

Produce up to 600 pcs/min, meeting large-scale demands while maintaining consistent product quality.

✅ Smart Servo Control System

Fully servo-driven system ensures accurate tension control, smoother operation, and reduced maintenance downtime.

✅ Flexible Size Adjustment

Quick and tool-free size switching to produce S/M/L/XL diapers in one machine — ideal for changing market needs.

✅ Soft & Skin-Friendly Design

I-shape structure provides better body fit and comfort for babies, improving customer satisfaction and brand loyalty.

✅ Modular Design for Easy Upgrades

Supports optional add-ons like frontal tape application, waistband addition, wetness indicators, and more.

🔧 Technical Highlights

Production Speed: Up to 600 pcs/min

Materials: SAP, pulp, nonwoven, elastic waistband

Packaging Options: Automatic stacking and bagging available

Power Supply: Customized per your country’s voltage standards

🌍 Built for Global Markets

Whether you’re supplying Africa, Southeast Asia, or Latin America, our machines are tailored for local voltage, raw material standards, and operator training.

💬 Customer Success Spotlight

“After installing the I-shape diaper line from Welldone, our monthly output increased by 35%, and product complaints dropped significantly. The smart tension control and stability truly make a difference!” — Factory Manager, Kenya

📞 Contact Us Today for a Custom Quote!

Ready to scale your diaper production with confidence? Reach out to Welldone Machinery for expert guidance and turnkey solutions.

👉 Email: tang@cnwelldone.com

📱 WhatsApp: +86-13655936189

🌐 www.cnwelldone.com