Top 5 Baby Diaper Machine Brands in the World—And How to Choose the Right One for Your Factory

Are you planning to scale your diaper production line—or launch a new one entirely? Choosing the wrong equipment partner could result in costly downtime, product defects, and major frustration.

After years of working in the hygiene machinery industry, we’ve studied, visited, and benchmarked factories powered by every major global player. Below, we break down the top 5 global brands for baby diaper machines, and show you what each one truly offers—not just on paper, but on your factory floor.

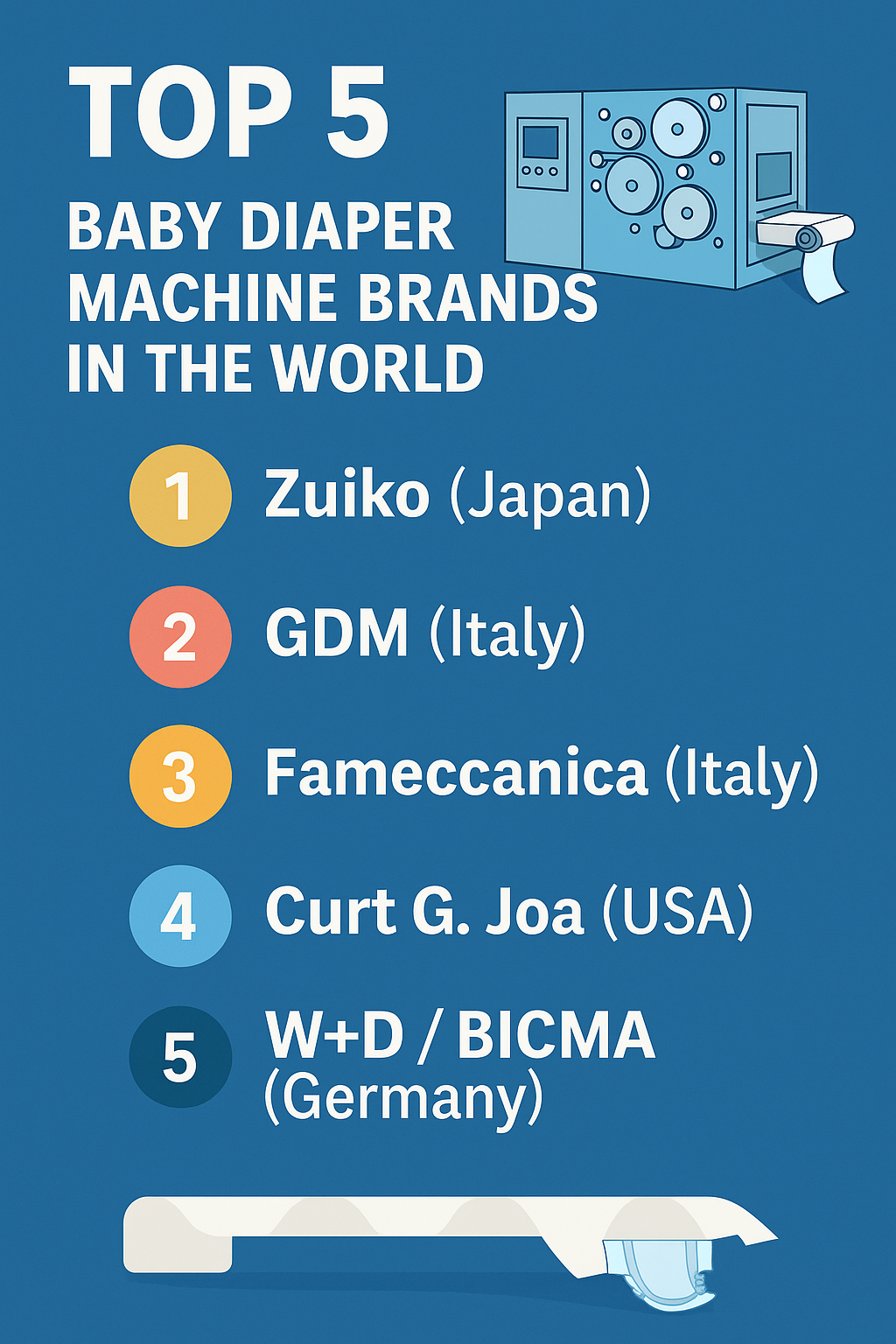

The Top 5 Brands for Baby Diaper Machines:

1、Zuiko (Japan)Zuiko

2、GDM (Italy)GDM

3、Fameccanica (Italy)

4、Curt G. Joa (USA)Curt G. Joa

5、W+D / BICMA (Germany)W+D / BICMA

Each of these brands brings a unique advantage depending on what matters most to your business: reliability, innovation, flexibility, speed, or integration.

1. Zuiko – Precision That Lasts Decades

Do you value reliability above all else?

Zuiko, the legendary Japanese machine builder, is known for long-lasting, ultra-consistent diaper lines that run with minimal issues for 15–20+ years.

Why Factories Choose Zuiko:

Built for long-term ROI

Heavy frames reduce vibration and maintain pad consistency

Minimal downtime with low spare part replacement needs

| Zuiko Strength | Impact on Your Factory |

| Ultra-Robust Engineering | Consistent product quality over years |

| Low Maintenance Design | Fewer breakdowns, lower repair costs |

| Clean, Accessible Layout | Easier for operators to clean and maintain |

Best for: Mature factories focused on long-term stability and low defect rates.

2. GDM – High-Speed + Modular Flexibility

Need to maximize OEE and speed while keeping the door open for future upgrades?

GDM (a Coesia company) provides high-speed, modular converting systems that are perfect for growing diaper businesses.

Real Advantage: GDM’s modular systems let you start lean and expand over time. Whether you need pant-type or taped diapers, GDM makes changeovers and add-ons simple.

| GDM Feature | Your Business Benefit |

| Modular Design | Easy to upgrade as product lines expand |

| Real-Time Quality Monitoring | Improves production control and reduces rejects |

| High-Speed Core Forming | More output, less waste |

Best for: Mid-to-large factories scaling fast or serving multiple SKUs.

3. Fameccanica – Innovation That Cuts Costs

Worried about SAP, nonwoven, or glue usage pushing up your costs?

Fameccanica, part of the Angelini Group, is the king of efficiency through innovation. Known for cutting-edge raw material savings, their machines offer patented glue and SAP application tech that reduce material waste without compromising absorbency.

In Action:

One South American client saved 6–8% on SAP usage per year using Fameccanica’s precision dosing system.

| Fameccanica Innovation | Cost Impact |

| Patented SAP Dosing | Lower absorbent material costs |

| Zero-Waste Edge Trimming | Maximizes use of nonwoven fabrics |

| Fast Roll Splicers | Prevents downtime during material changes |

Best for: Manufacturers focused on cost efficiency and long-term material savings.

4. Curt G. Joa – Flexible Machines for Dynamic Markets

Do you serve markets with frequent product changes or custom requests?

Joa, based in the USA, is a specialist in multi-size, multi-format machines. Their diaper machines allow for fast changeovers and are ideal for factories producing multiple SKUs on one line.

Unique Engineering: Joa’s cassette change system allows you to switch between tape diaper and pull-up pants—or between sizes—in under 30 minutes.

| Joa Flexibility Feature | Advantage |

| Quick-Change Cassettes | Change sizes/formats fast—respond to demand |

| Custom-Built Solutions | Tailored to your exact market and product goals |

| No-Waste Startup Tech | Reduces cost during product line restarts |

Best for: Brands needing rapid SKU changeovers or targeting multiple consumer segments.

5. W+D / BICMA – German Integration, End to End

Most machines focus on production. W+D also focuses on packaging—integrating production with stacking, bagging, and boxing. This makes their solution ideal for factories optimizing entire lines, not just converting steps.

Smart Investment: Their full-line systems can reduce labor by 2–3 workers per shift, increasing automation and consistency at the end of the production line.

| W+D System BenefitW+D | What It Means for You |

| Integrated Packaging | Lower labor costs, fewer packing errors |

| German Mechanical Precision | Fewer breakdowns, easier maintenance |

| Complete Line Engineering | Smoother transitions = higher OEE |

Best for: Large-scale factories focused on efficiency across the full diaper value chain.

Conclusion: Choose Based on Fit, Not Fame

These five brands all lead the world in baby diaper machinery—but they aren’t interchangeable.

🔧 Zuiko is for reliability

🚀 GDM is for fast, scalable production

💡 Fameccanica is for savings

🎯 Joa is for flexibility

🔄 W+D is for end-to-end optimization

👉 Your next step? Match your factory’s goals to the brand strengths above—or contact us to help analyze your needs.

📩 Email: welldone@cnwelldone.com

📞 +86-13655936189 | 🌐